Specific Utilities Of The Dry Moly Spray: Brilliant Choice For Outstanding Results!

Dry Moly Lubricant

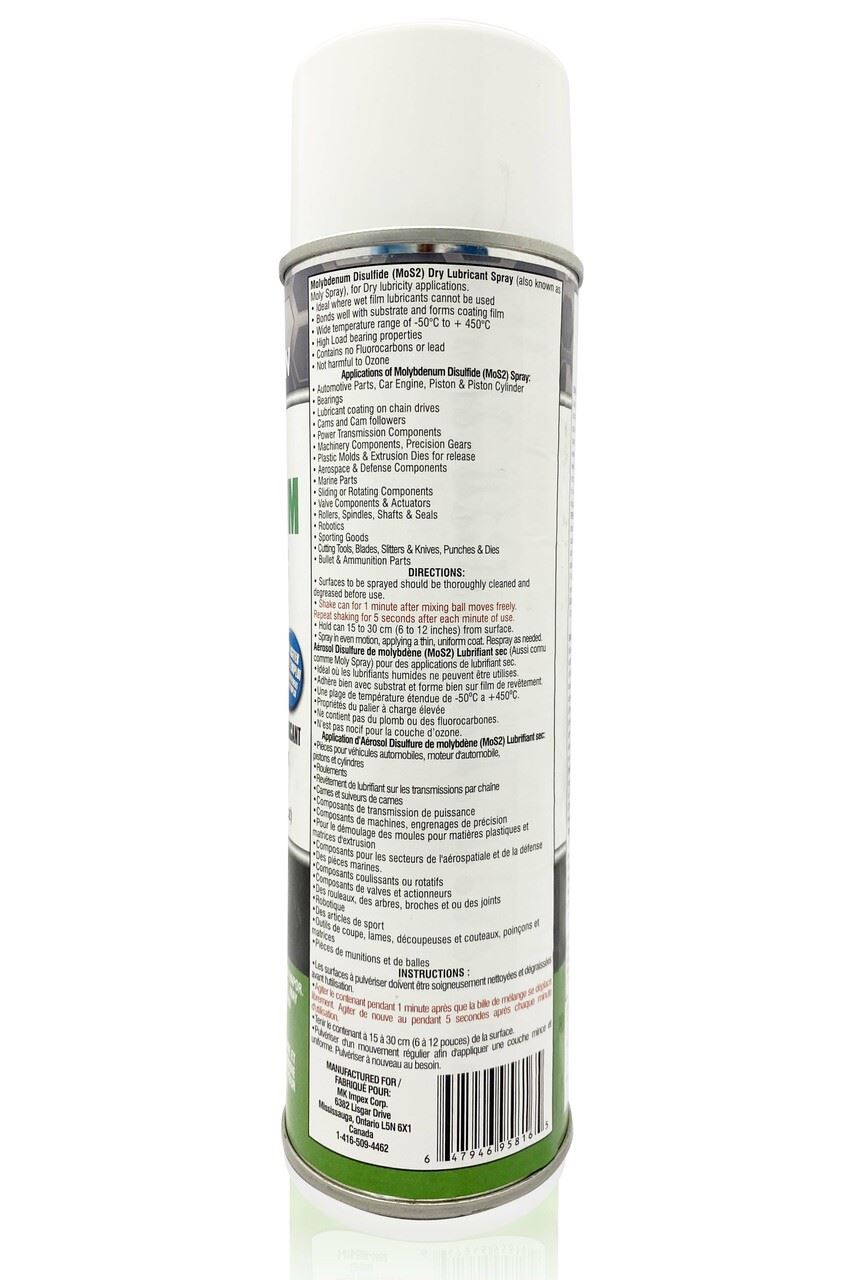

Lubricating industries are now going mad by the name of the dry lubricants. Instead of the liquid alternatives, it is always helpful to opt for solid lubricants. However, you can get these lubricants in different forms. There can be powdered particles or even sprays. The dry moly spray is one such brilliant choice for an outstanding result.

If you want the effectiveness of molybdenum disulfide to work fine, use the spray today. It is more convenient than powder. Therefore, go for this accessible medium to make your process lighter and hassle-free. Using the spray is effortless for the sliding surfaces. Enhance the lifespan of the concerned parts on which you apply this substance. Moreover, you have to check that this spray contains 99% pure form of molybdenum.

Excellent Benefits Of Dry Moly Spray

You can regard this excellent lubricant in spray form as an assembly lubricant. The examples of the sliding surfaces are;-

Cams

Slides

Plain bearings

Pins

With the adequate application of the lubricant, you can save the concerned surfaces from different kinds of damages. Dry moly spray will thus act magically if when two metals are colliding. There will be low friction between the two sliding surfaces with enhanced productivity. Thus, it is a more favorable substance rather than graphite.

Comparison With Graphite

Technically, the grease of graphite is better than the molybdenum graphite. However, you need to consider different factors like water resistance or resistance to a higher temperature. Such things are more effective in the case of the Molybdenum Disulfide spray. Hence, if you were usually graphite till now, it is time to bring a change.

Graphite is an excellent lubricant to resist the effects of high temperatures. But it will not be productive enough to protect the surface from wear. Furthermore, MoS2 sprays can resist extreme pressure also. This is one of the most impressive factors for switching to this substance. It is also a great choice for instant lubrication, irrespective of temperature.

The adherence capacities of molybdenum are outstanding. Get the surface hard and solid within a few minutes of coating. Thus, it will save you time also.