How Is Plastic-Recycling Done In A Plastic Recycling Plant?

Plastic recycling plant | Image Resource : 1.bp.blogspot.com

Plastic-recycling units have taken the responsibility of reducing the volume of plastic-wastes not only to project the environment and humans. Environmental-pollution has now reduced to a great extent with recycling of plastic-wastes in great volumes. Reputed plastic recycling plant has now adopted EPR-technology for accelerating and upgrading the plastic-waste recycling methods.

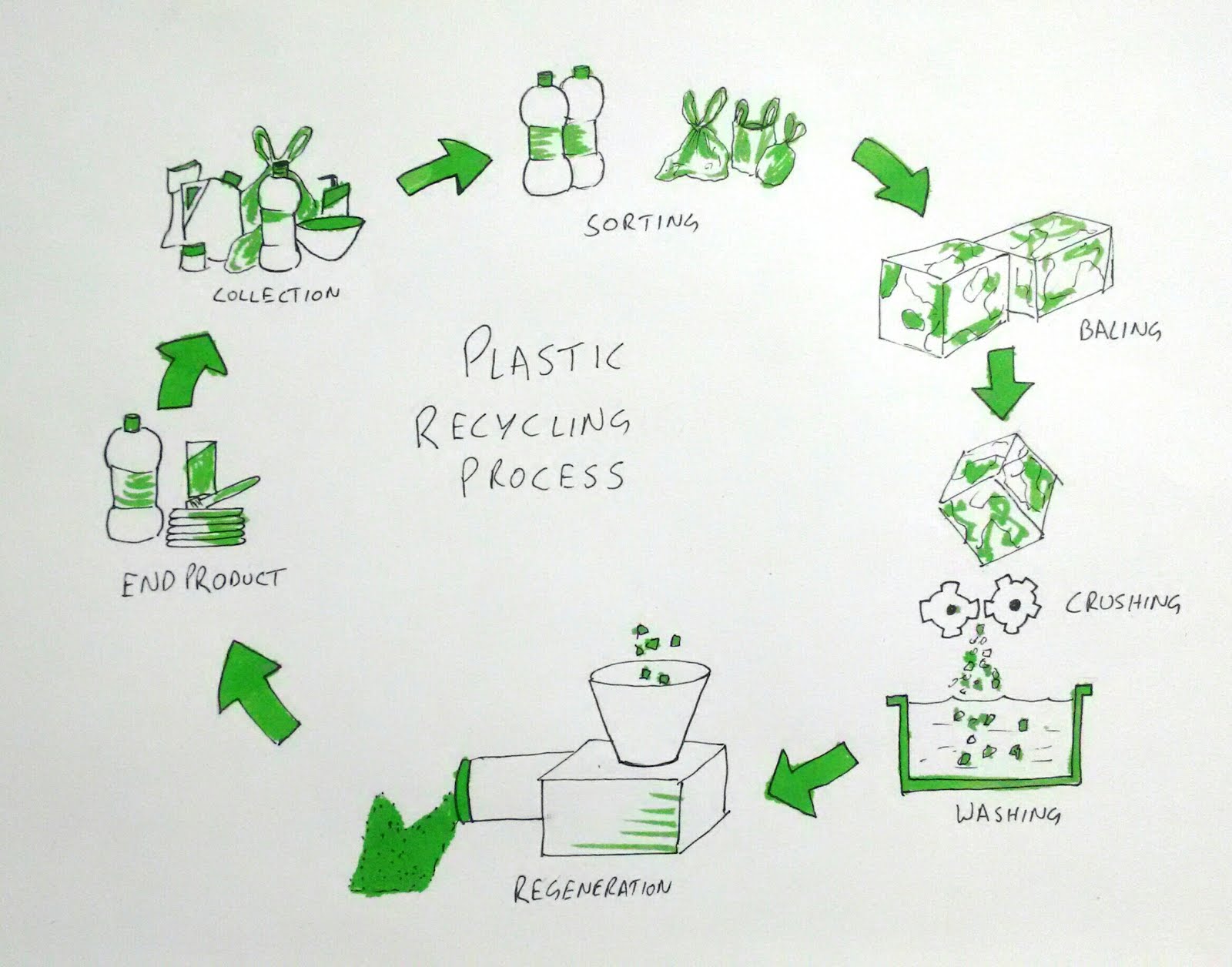

Steps involved in plastic-recycling:

Gathering plastic-wastes: First of all, scrap or waste-plastics are being collected in varied forms from multiple sources. However, there are some specific issues that will required to be focused on while collecting and accumulating the plastic-wastes such as reuse, material reduction, and so on. So that they can be sold to the plastic-recycling plants in bulk.

Sorting process: The collected wastes require to be gone through an advanced sorting-process so that plastic-types can be determined and categorized. This process helps in eliminating unwanted contamination as a result of which plastics get separated from other materials easily. Specialized devices are used in this process for making accurate and effective types of plastics.

Loading: After sorting, the plastics are being loaded in huge trucks so that they can be carried to the plants for processing or recycling purpose. Sorted-out plastics are being packaged nicely for customers to avoid any confusion in recognizing a product.

Shredding: In this phase, sorted-out plastics are cut into several pieces as per requirement. Lighter ones are being segregated from heavier ones in this stage so that proper processing can be done.

Cleaning: Special kinds of detergent-solutions are used for cleaning off dirt, wastes or other contaminations. The actual recycling or processing can be started only if the flakes are thoroughly cleaned.

Melting: Bulk plastics of the same category are melted in an intensive heat. The melting process usually plays a vital role in creating new forms or structures. Melted-plastics are usually converted into fresh plastic-granules and these granules are needed for creating fresh structures.

Classification: Plastic-granules are gain sub-categorized into different categories for easy recognition and utilization. Only experts can deal with the concerned task well. This identification helps in increasing plastic-manufacturing productivity to a great extent.

These steps are religiously followed by all standard plastic-recycling units of the modern era. Nowadays, most of these plants are using advanced recycling-devices for accelerating the recycling-procedure. These devices have directly facilitated easy handling of manufacturing of fresh plastics in bulk. In fact, it is for these devices that recycling-plants are now getting more and more plastic-recycling projects.

8

Kudos

8

Kudos