Glass Polishing Additives: Properties and various usage

Glass polishing is not just a household requirement. It is also needed industrially. In fact, the industrial use of glass polishing is much wider compared to its household use. The optical glass industry is the most prolific user of this chemical. Indeed, this is a chemical that is made up of a number of metal oxides.

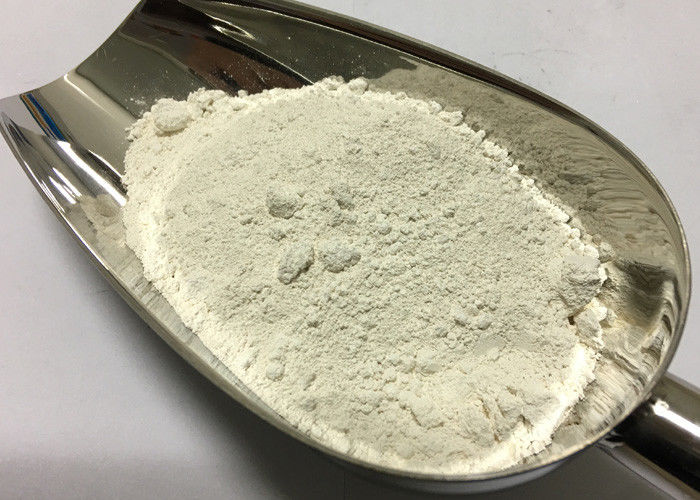

Glass Polishing Additives

The main component of glass polishing powders is cerium oxide. However, it also has other constituents such as Lanthanum Oxide, aluminum oxide, silicon oxide, calcium oxide etc. Glass Polishing Additives have a strong polishing character which his mainly due to its ability to precisely cut through glass surfaces. The powder contains nanoparticles of all the oxides. Owing to nanoparticles it has a large surface area. This makes it possible to cut through various scratch marks precisely.

Use of Polishing Additives

Polishing additive is used for removing scratch marks from various glass surfaces like furniture tops. However, it is the industrial customers, the chief of which are the optical glass companies, which use this powder extensively. Optical glass industry has a huge array of application for Glass Polishing Additives. They are used to polish different types of glass surfaces like borosilicate glass, quartz glass etc.

Use Of Additives In Industry

The optical glass industry depends on this additive for precision polishing since they need perfect polish. However, this additive is used in the optical glass industry not just for its ability to polish, but also for its effect as UV filter. In fact there is a class of glass Polishing Additives which also act as UV stabilizer. This is a very useful property for optical glasses of various types.

UV light blocking character of polishing additives

These additives help to mitigate the conditions arising out of harmful UV radiation. These additives can protect the product and help to bring down field of vision failure as well as improve resistance against weather conditions and also enhance durability. Some of these can also protect against premature fading of color. In effect, they enhance shelf life for glass products that contain ingredients which are sensitive to light, especially UV light.

This indicates that apart from cleaning glass surfaces, these additives can also enhance the life of glass products by preventing premature degradation of glass surfaces. They can also contribute to reduced field of vision failures and enhanced durability resulting in enhanced shelf life. You can also mix polishing additives into polishing powders and use the powder effectively. Polishing with these products renders glass surfaces look new. It can eliminate surface scratches which impart a perfect finish to glass.

This also means that you don’t need to polish it frequently as the polish is quite long standing in nature. It can also prevent formation of abrasive sediments on the surface.

However, these chemicals are available in a number of grades depending on the use. There are inferior, moderate and superior grades. In the industrial scenario, it is the superior quality that is always used since they need perfect polish. However, for household use, you may do with a moderate efficiency powder. In fact, for removing scratch marks from household glass surfaces, it is okay to use the moderate efficiency ones.